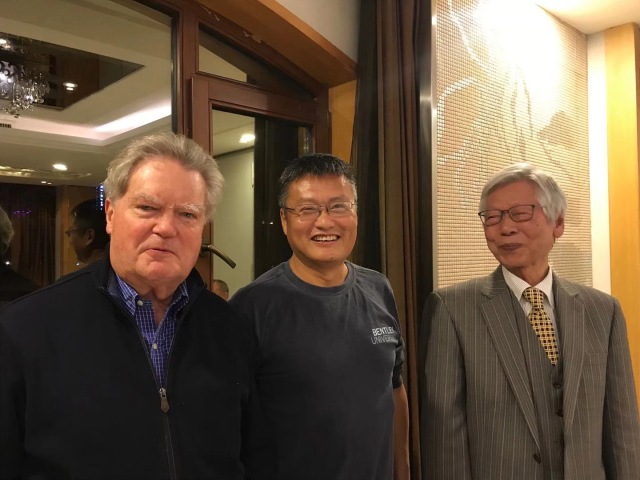

Sea Eagle and our Korean supplier team members after dinner in downtown Bupyeung, Korea. Ryan Healey, our Sea Eagle inventory manager, is the second guy on the left and I am the gray-headed guy on the right.

By Cecil Hoge

In November 2019, I returned from my last trip to Asia.

I began visiting Asia in 1973, starting with Tiawan, Hong Kong and Japan. In the 70s and 80s I went to Asia every few years and most of those trips were to Japan. In those years, Japan was feeling on top of the world. Toyota, Honda, Nissan had conquered the small car and mid-size car market. Real estate in Japan was booming. Japanese electronics led the world. And if you chose to have Kobe steak for lunch in Tokyo, it could set you back $150 to $200 for one sitting.

At the time, I was selling Frog fishing lures in Japan. It seemed that our SuperFrog™ lures we had developed in the States had a true market in Japan. After World War II, GIs introduced American bass fish to many of Japanese lakes and the new sport of bass fishing was born in Japan. And for a while we rode that wave and sold over 50,000 SuperFrog™ lures in Japan each year for about 5 years from the late 70s to the early 80s. In those years, I would go over once a year and meet with the buyers at Diamaru, which was the Japanese department store/trading company that I was dealing with.

The meetings were always intimidating since you would meet with 6 or 7 people in a large conference room, talk to them for about 45 minutes, give them your sales pitch and then someone would get up and say, I have to talk to my boss. The guy who said that and 2 or 3 others would get up and disappear from the room for another 45 minutes. Then all 3 or 4 of the original participants would file back into the room and say that they would send a telex or fax (those were the 2 modes of international communication at the time) informing me of their decision in about a week. Usually, they were good to their word and a week or two later a telex or a fax would arrive with an order.

By the late 90s I was going to Asia every 6 to 12 months. By that time, we had moved our inflatable boat production from Italy and France to Korea and China. Most of my trips were to Korea and China, with some stopovers in Hong Kong. All of these trips were either to investigate suppliers or to meet with suppliers for the products that we were selling. We make Sea Eagle inflatable boats in Korea, Vietnam or China and we also make our Panther Martin fishing lures in the Dominican Republic and Southern China.

This last visit to Asia was a relatively short for me…3 days in Korea, 3 days in China, 1 day back to Korea and then back to the States. The total travel time was 8 days, including the time lost on plane travel. That’s because of the weird time zone differences. Asia time is 12 to 14 hours ahead of us. It takes a whole day to get to Asia, but because of the time zone difference, it is more than a whole day later. And then, by a miracle of time zone travel, it takes zero days and zero time to get back.

How so, you may ask? Well, the flight from JFK to Seoul going takes 14 hours. On this trip I started out at 1 pm Saturday, November 2nd and arrived at 4 pm Sunday, November 3rd. Coming back was even more exciting. I started out at 10 am on November 10th and arrived, after 14 hours on a plane, at 10 am November 10th in New York. So, clockwise and date-wise, the return trip took no time.

This trip was not so short for my friend and colleague, Ryan Healey. Ryan is our inventory manager and after I came back from Weihai, the northern Chinese city we were visiting, to Korea and the States, Ryan headed, by train, to Qingdao, another Chinese city in northern coastal China. Then Ryan went down to Shanghai, also by train. Then, after a day in Ningbo, the port city of Shanghai, Ryan flew South to Dongguan and Shenzhen in southern coastal China for a couple days there.

But that was not all for poor Ryan. After enjoying those 4 Chinese cities, Ryan then would go down even further South to Vietnam to visit our Korean supplier’s Vietnamese factory. There is no rest for the weary business traveler. After that, Ryan would just have to take a plane back to Korea, hang out a day near the airport and then fly out to the States. His trip is exactly one week longer than mine.

Frankly, Ryan’s schedule was the normal I maintained in my earlier Asia trips, usually taking one, two or three days to visit each supplier, and then maybe a couple of days to check our one or two more new suppliers and then back home. So, the total time most of my Asian trips took two to three weeks.

Recently, I have cut back on the length of my trips, primarily to get back home faster to my wife and family. Ryan got the short straw on this trip and was scheduled to visit all 5 of our Asian suppliers. That, my friends, is just normal business travel. Hundreds of thousands of American business men and business ladies make this kind of trip each year and sometimes they make those kinds of trips several times each year.

On this trip, we were picked up at the Incheon airport (that is the main airport for Seoul, Korea) and driven into the town of Bucheon, a suburb near Incheon. For those of you not familiar with Korean geography, Korea is a peninsula of land jutting out between the Yellow Sea on the South and the North Sea on the North. Seoul is near the top of South Korea, about 30 miles from the DMZ (Demilitarized Zone) – the border between North and South Korea. It is interesting to note, roughly 50% of the total population of Korea is located in and around Seoul. So there are 30,000,000 Korean folks in and around Seoul and 30,000,000 more Korean folks in the rest of Korea.

After getting picked up at the airport by our supplier’s company driver and a new young employee, Gray, we were whisked into downtown Bucheon to something called the Koryo Hotel. The main virtue of the Koryo Hotel is that it is within walking distance of the downtown restaurant district. So, we checked in, dropped our bags In our rooms and headed out for dinner in Korea with Gray, the new employee of our supplier. Dinner turned out to be a favorite of mine – Korean barbecue – which, in this case, featured different kinds of red meats and vegetables cooked on a barbecue grill in the middle of our table. It was yummy and after dinner we headed back to the hotel to crash for a well-deserved sleep.

The next day we were downstairs bright and bushy-tailed as some would say. The driver and Gray were there to take us off to their new factory premises in Bupyeong, a nearby town. A word here is important. Our supplier had just gone through some difficult economic times. They had been on the Korean Stock Exchange cresting the wave of popularity of inflatable standup paddle boards. They were among the first companies to produce inflatable standup paddle boards and they got an early lead on the market, boosting sales of iSUPs (inflatable standup paddle boards) from almost nothing to over 60,000 units a year.

Their expansionary dreams did not stop there. They decided to get into the apparel business and began opening stores in various shopping malls around Korea. Pretty soon they were up to 30 stores. Unfortunately, the apparel business proved more difficult than their core inflatable boat and SUP businesses. It seemed that apparel was a very competitive field and having nice looking outdoor sporty clothes was not enough. Store rents in the new shopping malls that they had picked proved very expensive and sales were lackluster when they needed to be gangbuster. Within 3 years of initiating that business they found themselves losing some serious money.

As luck would have it, or what I would call “Murphy’s Law” – that is, “whatever can go wrong, will go wrong” – took effect. Just as it was becoming apparent that the apparel business was is serious trouble, new and unforeseen problems arose in the core inflatable boat business. As their sales of iSUPs were peaking, literally hundreds of new startup companies entered the fray and my supplier found themselves dealing with lots of competition, most of it at much lower prices.

As if that was not enough, a part of the original core business, inflatable transom boats with fold-up floorboards began to collapse at the same time. The market had decided to move away from that kind of craft and instead move to what is known as inflatable RIBs. These are inflatable boats with either a fiberglass or aluminum bottoms permanently attached to the inflatable portions. It seemed that the public did not want to deal with inserting and setting up floorboards in a boat. So new consumers chose to buy inflatable RIBs, which, by the way, stands for Rigid Inflatable Boat. What the consumer got was a far easier to set-up boat that was considerably heavier and way more expensive, but a boat that motored much more like a traditional rigid fiberglass boat for the simple reason that it had a rigid bottom.

So this trend away from a core product that they regularly produced to a product that they did not regularly produce, combined with problems in the apparel business, combined with problems in the once booming SUP business all came together at the same time and created a sudden collapse in sales and some quite substantial losses. This is the very heart of “Murphy’s Law” because “whatever could go wrong did go wrong”.

To come back to my trip, one the important reasons I was going to Korea was to see just what the real status of my supplier was. I knew they had moved out their quite elegant headquarters, I knew their new factory location was in a really down and out looking area, with narrow winding roads going up and down little hills and cars, trucks and vans parked precariously on the edges of the roads. I knew this because we had checked out their new location on Google Earth.

What I did not know what their actual new facilities were like and what their financial condition truly was. So this was, in addition to being regular visit to a supplier, an exploratory trip to see and understand what really was going on.

My concerns were considerably appeased when we pulled up to their building. It was a large, relatively modern looking that stood out among the the smaller and more dilapidated shantytown buildings. In the building we soon found many of the former features of their last, more elegant headquarters. There were numerous conference areas with nice big tables for multiple people to have discussions. The owner had a nice open office with seating for 6 or 8 people to have more private conferences and what I would call “quality face time”.

In their offices for lengthy discussions on market trends, individual sales and and new products

Before seeing the Korean factory and the other warehouse areas of the factory, we sat down for discussions, first with the owner in his office and then in a conference room set aside for our discussions. Generally importer/supplier discussions follow a familiar path, first discussing general market conditions, problems areas, new factors facing both companies. Of course, in this case, this included a discussion of the financial difficulties that my supplier had faced in the last year and how they had dealt with those problems.

They were quite open about the difficulties that arose and how they had to work around them. They had to cut their staff in Korea from over 150 people to less than 75, they had to sell several buildings to pay off losses and secure future financing. They had now closed all their 30 stores and had exited the apparel business and their new plan was to concentrate solely on their core inflatable businesses.

All of this was very important for me to hear. I immediately felt that they had taken many important steps to secure their survival and long term recovery. I was sympathetic because I went through my own set of financial problems in the late 80s – I would refer anyone who wanted to learn more about that to read my blog story: “How The Stomach Eliminator Almost Eliminated Me” – it is a harrowing tale of lackluster sales, followed by booming sales, followed by collapsing sales.

Now, of course, everyone puts their own spin on things and no doubt what I was hearing had some spin. As my uncle once said to me: “It is all right to have your own press. Everyone has their own press, but it is fatal to believe your own press.” With that in mind, I was encouraged to hear about how they faced the problems they had and it did seem to me that they had made many of the hard choices a business faces from time to time and were emerging as best could be expected.

With plans for recovery revealed, we went on to other subjects:

The state of the inflatable SUP market – SUP sales were peaking, with cheaper and cheaper entries still selling large volumes and still coming into the market. Higher priced brand name SUPs were flat or declining, low end price point online sales accounting for 80% of the overall volume.

The state of the inflatable kayak market – Still healthy, but also plateauing. Fishing kayaks still vibrant and growing.

The state of the transom inflatable market: dead as a door nail.

The state of inflatable fishing boats: a small, but growing segment of the market.

We discussed worldwide sales:

Fading kayak and SUP sales in U.S.

Kayak and SUP sales still increasing in Europe, but generally, the larger inflatable boat market was down.

We discussed the state of tariffs in the U.S. and their effect elsewhere:

Now this is a subject affecting all importers whether they were paying tariffs or not. Since our Korean supplier was making boats for us in Korea or Vietnam, none of those products were subject to tariffs. However, since we also were importing other inflatable products from other suppliers in China, those products were sometimes subject to tariffs.

Here I had a lot to say:

We had started out the year (2019) in great fear because of the subject of tariffs. Tariffs of 10% were instituted in September of 2018 on inflatable boats and kayaks made in China. For those of you don’t know, inflatable boats and kayaks made in

China represented 87% of all those sold in the U.S. So, effectively, almost all inflatable boats and kayaks sold in the U.S. were made in China.

By July of 2019, tariffs on Chinese made inflatable boats and kayaks increased to 25%. In our case, 40% of our boats were Chinese made and subject to tariffs. By August 2019 we had already paid over $240,000 in tariffs. This had forced us to raise prices on those boats made in China and immediately caused a sales decrease of most of the boats we raised prices on. It was a true case of economics 101.

However, things changed when we applied for an exemption on tariffs. Our case was based on three facts:

1. Certain kinds of inflatable boats could only be made in China.

2. There was no inflatable boat industry manufacturing inflatable boats in the U.S.

3. Inflatable boats and kayaks posed no risk to the security of the United States.

Now, we got assistance in our effort to file for an exemption on inflatable boats from the NMMA – National Marine Manufacturers of America. They wrote a letter of support which stated that inflatable boats were important to the overall boat market in the U.S. because they introduced many people to boating and that fact helped American Boat Manufacturers because in the future some of those people would buy rigid boats manufactured in the United States. That, of course, helped since their letter was attached to our exemption application.

My brother John, being a Republican, (something I am not), was also able to get a second letter from Lee Zeldin, a New York congressman, stating tariffs would hurt our ability to hire people on Long Island. While that is 100% true, I am personally dubious that we would have had much effect on the economy of Long Island. Anyway, considering the fact that Mr. Zeldin is a friend and ally of Mr. Trump, his letter was probably also very useful.

Perhaps, the most important fact about applying for a tariff exemption is that my brother and our inventory manager, Ryan, came into our office early one Sunday, in order to hit the send button on our exemption requests the instant the government website came up allowing people to make exemption requests. That resulted in us being the very first product to make an exemption request in the United States on what is known as list number 3. So, being the very first on the list also helped. We applied for 17 separate product exemptions and all 17 were filed within the first hour of the government website being up.

I have to say that while I fully supported making exemption requests, I was very dubious that our requests would be granted. Yes, we had truly valid reasons for our requests. And truly, importing inflatable boats, kayaks and SUPs was no threat to American security or to any American manufacturing company producing inflatable products, so those points were in our favor. In spite of that, I felt we were just too small a category of products to be considered. In retrospect, the size of our category may have been part of the reason we actually got the exemption.

So, surprise, surprise, we were granted exemptions on 7 products. Now you might think that meant that just those 7 products would be exempt in the future. But, that is not the way the government works. The government decided to give an exemption for the categories of inflatable boats, inflatable kayaks and kayak paddles. We had thought the exemption would be granted to just us, but that was also not the case.

Now, here is the strange part: we were the one and only inflatable boat company to apply for an exemption, but the exemption we got was for all inflatable boats and kayaks. However, since we were the only company applying, the specific exemptions for inflatable boats and kayaks were written around the specific boats and kayaks we applied for. So the exemption was for inflatable boats or kayaks made with PVC/polyester fabric that weighed under 52 kilos (114 lbs.) or 22 kilos (48 lbs.). This is truly case of the squeaky wheel getting the oil.

Regarding my assumption that getting an exemption was like winning the New York lottery, that was not far off. As of the end of December 2019, there have been over 31,000 requests for exemptions on list # 3. So far, about 5000 of those requests have been reviewed. Of the 5000 reviewed, less than 500 requests have been approved. Since we had 7 of those requests approved, we were over 1% of all the approved requests. So, in a way, I think it is fair to say, we did win the New York lottery.

While we had informed our supplier earlier of this fact, we had not given them a first hand, blow by blow description of what happened. I took time on this visit to give a complete rundown of what the present status of tariffs in the U.S. I also mentioned an important fact for them to remember about our tariff exemption: the exemption is only good for one year. Therefore, as of August 7th, 2020 we will either have to re-apply for an exemption and get it or we will have to pay 25% tariffs on all inflatable boats and kayaks received from China after August 7th, 2020.

Here, you have to understand the position of our Korean supplier: They do have two factories in China producing inflatable boats for them, so for those boats going to the U.S., they would not have tariffs for the time being. That would be helpful to them. However, since the boats we are producing with them were only coming from Korea and Vietnam, those products would not have tariffs anyway.

Since our supplier was one of the few companies who could make boats, kayaks and SUPs outside of China, this subject was of great importance to them.

That is not the end of the tariff story. There were other new points to discuss. As of September 1, 2019 new tariffs of 15% have taken place which affect Inflatable SUPs and the fishing lures that we also happen produce in China. Added to that there are continuing tariffs on boat accessories which include oars, foot pumps, piston pumps, electric pumps, carry bags and many other accessories.

All I could tell my supplier for the moment was that the overall tariff situation was “cloudy”.

I have to add a postscript to my conversation to my supplier – After I returned home, just before December 15, 2019, there was an announced “Phase 1 Deal”. That reduces the September 1 tariffs from 15% to 7.5% when “Phase 1 Deal” is signed. At the moment of writing this, the “Phase 1 Deal” has now been signed. So, the 15% tariffs are now 7.5%.

I spent a good one hour explaining all the ins and outs of this. Part of the reason that I came to visit my Korean supplier was to be sure that they would be ready to be an alternative supplier if the trade war took a turn for the worse. We had been given a reprieve because of our speedy exemption requests, but that had a deadline: August 7th, 2020 and in the meantime, there were still other tariffs in effect that we had to work around.

What I wanted to say to my supplier was that the situation was unknown and fluid and we had to adjust to whatever comes about. Since our supplier had many American customers they knew already most of this situation. The fact that we had secured the exemption for inflatable boats and kayaks was perhaps not fully understood by them, but after my meeting I think they were totally clear on the present situation and what twists and turns the future might bring.

That done, it was time for lunch. We adjourned to the company lunch room. The owner had prepared a nice 50 course plus Korean lunch for that. A German gentleman and his lady assistant were at lunch along with about 8 other employees from the company, most of whom I knew from my many visits to the company. The German couple proved interesting. They were importing some SUPs and kayaks to Germany under the name Da Vinci. I am not sure what that Renaissance gentleman had to do with inflatable standup paddle boards. I think the point was that these paddle boards where designed by like geniuses.

It gave me an opportunity to try out my rusty German which had not seen much action since 50 years ago when I worked a summer in the Black Forest. I was able to get a few points across and least encourage these new entrepreneurs. It seemed that they had been wending their way around Asia, photographing scenic paddling spots in Thailand and elsewhere for their next year’s catalog. They were an elderly couple but they seemed quite optimistic about the prospects for their SUPs and kayaks in Germany.

After tasting about 25 of the 50 different courses, most of which were delicious, even if I was not able to identify exactly what I was eating, we went back to the office for further discussions. It was now time to discuss the new prototypes. I had two major goals in mind for this visit:

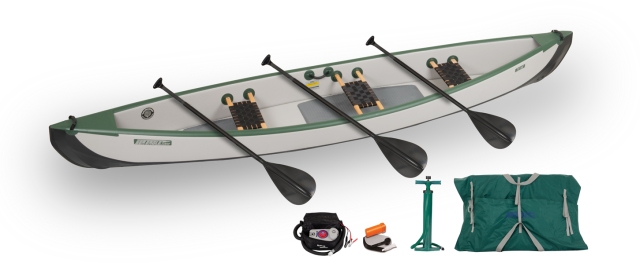

1. Outfit our Travel Canoe with traditional wooden seats. This product, which is a unique patented design of ours was normally produced for us with inflatable seats. While the inflatable seats very comfortable, they were not appealing to traditional canoeists. I concluded, rightly or wrongly, that I might greatly increase the sales of the Travel Canoe if I could just accomplish that simple task – that is, offer traditional wood seats with this canoe. It was not as easy as it sounds.

2. Create a new model transom boat for the flood/rescue market. We had sold several hundred transom boats to fire departments around the country over the years, but we had never really focused on that market. The changes I envisioned were simple enough: add fabric re-inforcements where the boat might hit sharp objects, increase the strength of the D-rings and handles, add reflective strips so the boats could seen at night if a light was shone on them, offer a super rigid, high pressure drop stitch floor for incredible buoyancy and flotation. Again, all these changes sounded simple, but in fact, were not.

Here is a picture of the two boats we were working before final changes – the seat attachment system for the Travel Canoe (in front) looked good, but did not work and required some later modifications.

After some discussion of important points for the new prototypes, we adjourned to the factory floor. This was of interest to me because now I could see how their new factory floor was set up. The space was smaller than the previous manufacturing space, but it was still quite respectable. They had a large open space for the factory floor. At the moment it was fully occupied with making a boat order for the Korean Army of 100 inflatable transom boats. That was great since the flood rescue boat we were making had many similar features to the Korean Army boats, even if the Korean boats were designed more for troop transport than for flood rescue. In any case, both the boats they were producing and the boats we wanted to produce had one thing in common: they had to be as tough as nails. That was good from my prospective.

We went over to the area where they had our two prototypes set up. While they had completed the overall structure of each boats, they had not added the final details to boat, primarily because we were still discussing what those final details would be. So that afternoon, we discussed in detail just how new seats would fit on the Travel Canoe. My idea was to do it with D-rings (as shown above), which we knew were very strong and capable of taking over 500 lbs. of weight. The wooden seats not only had to be strong, but also the connection holding the seats had to be strong. That is because some Americans weigh 300 lbs. or more and they tend to be very disappointed if a seat collapses.

We decided that using stainless steel snap pins and D-rings would allow the paddler to easily put on or take off their seats and provide safe seat attachment system. That theory proved to be false, but I will come back to that later.

We went on to the transom flood rescue boat. The first problem we discussed was plastic handles. We had used these handles on our standard transom boats since 1997 and thought they were pretty bulletproof, but the fire experts we showed the boat to told us they were a total no go. The handles could bent when rolled up with the boat and when bent that made it difficult for these beefy guys to get their hands inside the handles.

We explained to the firemen that that could easily be solved by hitting the handles with some hot air from a hair dryer And the hot air would magically revert the handles back to their original shape, but that was also quickly shot down. Firemen had no time for plugging in hair dryers, they had to be ready to instant catastrophes and so they needed another kind of handle that would never suffer this kind of problem.

The new fabric handle did look great and was tough as nails

So, after some deep discussion of this problem, we came up with a far stronger fabric handle with a nifty PVC fabric covered with black PVC tubing that I was sure would bring tears of joy to any self-respecting fireman.

There were other issues to solve: it seemed that the heavy duty D-rings that we had selected for the inside were a little too high for the fire experts we were consulting (we had e-mailed them a pic), so we determined get a new prototype made.

The last point of discussion was on the drop stitch floors. We have been using drop stitch inflatable floors on both our transom boats and many of our kayaks for over 10 years. Drop stitch construction, for those of you who do not know, is a system of two layers of fabric with hundreds of thousand of 1000 denier threads going from one layer to the other. It is an important breakthrough in inflatable boat design that allows the construction of flat inflatable surfaces and flat inflated side walls. Hence, our Travel Canoe is made with drop stitch construction which creates flat and very rigid sides and floor and a true canoe shape. That construction system also makes it possible to make standup inflatable paddleboards that are virtually as rigid as fiberglass paddleboards.

So we went on to a discussion of how to make the drop stitch floors in the rescue boat even more rigid and even more rugged. Why, because our intrepid firemen wanted to be able use our fire rescue boats with up to a 40 hp motor. That meant that the boat transom had to be able to take that weight and more importantly, the drop stitch inflatable floor had to be able to not flex when powered by a 40 hp motor. After much discussion we decided to re-inforce the drop stitch with carbon fiber strips. Because carbon fiber had no stretch and PVC polyester (the base fabric of the floor) has some stretch, the added carbon fiber would greatly improve the rigidity of the floor.

By this time the hour was getting towards 6 pm Korean time or about 4 am back home. That meant it was time to close down discussions for the first day and go have dinner. That night we were invited by the owner to a big traditional Korean dinner along with the German couple we had lunch and 4 or 5 other company employees.

So off we went. We drove down some back roads, some major highways and then down some other back roads in some other part of the area. It was dark already, so it was not possible to see much. Within about 20 minutes we arrived at our destination.

Here we are with the many courses! I am the second to last guy on the left.

Dinner was fabulous and I tasted at least 37 of the 85 courses and I was good with it all.

After dinner, we all walked over to a coffee, tea, milkshake place – I was disappointed because they did not have my beloved vanilla ice cream, but I settled on green tea. By 8 o’clock we were back in our hotel for our second night in Korea. That also gave me an opportunity to call my wife, find out how things were going at home and report on how my trip was going. After that, there was still time to listen to rock on my Bluetooth speaker and ponder the trip so far.

The second day in Korea went quickly. We had a kind reiteration of our previous conversation going over most of the points from the day before. We had some time to sit for a few minutes with the folks from DaVinci SUPs and kayaks. They seemed quite nice and energetic, especially considering the fact that they were in their 70s. I gather their business model was more a labor of love than a new way to build an empire. The Da Vinci name of the company was the brainchild of the German gentleman I was talking to and he was very enthusiastic about his SUPs and a new version kayak he was making that had many similarities with the RazorLite kayaks I had previously developed and patented in the U.S. In any case, he seemed very happy to be going around Asia photographing his SUPs and kayaks.

That sounded like a pretty good marketing idea to me although I had a feeling my wife would not agree to such a sentiment.

Within no time, we found ourselves back in the executive lunch room for another fine Korean meal. After lunch, we went off to the factory floor to see the status of our prototypes. Frankly, not much had changed. The new handles were on, but almost nothing else done. More distressing, the owner came down to see our seat attachment system on the Travel Canoe. He decided to jump up and down on it and that went well, but after that, on a whim, he gave the seat hard slap from underneath and to my horror, the seat pin popped out and the seat disengaged from the hull. Oops, that was not good, especially, if you happened to be running down a white water river. Imagine the seat going east while the canoe went west.

Immediately, we had a powwow about this new problem and decided we needed a new solution. By that time it was already late in the day and quite obvious that whatever solution we countered upon would not be solved that afternoon. The factory owner suggested heavy duty side grommets with cotter pins and split rings. It sounded pretty good and that was the solution we settled on. Of course, it was simply too late to implement that change there.

Since time was running short and the factory was about to close down for the evening, we decided we would come back to the factory the next morning before our flight out Weihai, China.

For that evening some of the long-term employees decided to take us out for Chi Mek, which is kind of chicken dinner. Fortunately, the Chi Mek place was right around the corner from the hotel. So, after Ryan and I dropped our business bags in our rooms at the hotel and after I made a quick call to my wife, Ryan and I came down and walked out to join the Chi Mek dinner folks. This dinner include a couple people we had known for over 10 years, so there much good feeling about the semi-casual meal.

But hold on, it was not so casual that we would not have 30 or 40 different entree courses to nibble and taste. Besides some fried scorpions, tasty shrimp there was one delicacy that caught me eye. It was was a bowl of silkworms, deliciously soaked in some kinds of herbs and spices. Are you ready!

Here it is – ready or not – some yummy silkworms!

No matter, the silkworms were actually pretty good. I am sure they gave strength and health to my body and so it was.

From silkworms to other delicacies to delicious chicken…it was all good and we had great time.

The conversation did take a little left turn when I made the mistake of asking what was going on with South Korea and the rest of Asia. I expected to hear about the problems with their neighboring country: North Korea, but I was wrong. It seemed that Larry Lim, the production manager of the company, was particularly upset with Japan. In an effort to get his points across most accurately he asked another associate, Ray, to translate.

Larry soon launched into an excited conversation about Prime Minister Abe and Japan. I was not expecting that. Abe was a kind of Hitler, Larry explained, who not only had not apologized for the “comfort women” and who intended to invade South Korea.

This was news to me. I knew about the “comfort women”. This was a really sore subject in Korea because during World War II, Japanese soldiers occupied Korea. In doing so, they took many Korean ladies to be the “comfort women” of the Japanese soldiers. Now, you can easily guess what that might entail and you can surely see why this was and still is a very sore point between Koreans and Japanese. From the Korean point of view the Japanese have never officially and properly apologized about the “comfort women”.

I knew about the comfort women situation and I had always been sympathetic to the Korean feeling about this. After all, it was a truly terrible thing that happened during World War II. That said, it was now over 70 years ago, so you would think tempers had calmed down by now.

Apparently not, and apparently, there was now a prevalent feeling in Korea that Japan intended to invade South Korea. That was news to me. I asked some of the younger people at the table about this. In particular a younger lady next to me named Carrie Park who had only recently started working for the company. She was not so sure Japan represented a great threat, but then again, after some more questioning, she was not so sure that North Korea represented a great threat.

Now, having been to Korea 25 or 30 times, having visited both Korean and Chinese exhibits on the Korean War and having read the 3 histories of Korea, I could think of the situation between South Korea and North Korea as still very dangerous. But I was truly surprised by Larry talking about the antagonism between South Korea and Japan. I know that they were arguing about a trade pack between the two countries and I know that they had suspended an arms agreement recently, but I did not think the situation as that serious until Larry spoke up.

Jinny Park, a lady we had worked with some years, kind of represented the middle ground between the younger ladies and the older guys. She also was very concerned about the Korean/Japanese situation, but, perhaps, not as concerned as Larry Lim. Jinny was Heiley Im’s boss. Heiley was our new contact, in charge of managing our account.

Anyway, our conversation about that South Korean/Japanese situation was very colorful with various folks raising their voices in excitement and throwing in comments. I could say that there was definitely was a young/old divide regarding this situation with the older Koreans seriously concerned about the situation and the younger folks almost blasé about it.

I came away with impression that the younger members of my supplier had heard about these problems from their elders so long that they no longer felt they were real, while the older members, having mother’s and fathers who actually had been in the Korean War and had seen the Japanese occupation of Korea, were much more more concerned about the situations with both North Korea and Japan.

Needless to say, we did not solve any problems, but we had a great time talking about them. And the meal, while not elaborate, was truly delicious and fun was had, I think, by all.

We were back in our hotel rooms by 9 am, well fed and maybe not the wiser, but in plenty of time for a good sleep.

The next day went pretty fast. By 9 am we were at the factory. We talked with the owner and Heiley, discussing some of the general issues surrounding our relationship. By 10, we were downstairs discussing specifics of the two prototypes. We really were not much closer to a resolution of all problems – after all, there was no time to realize final new samples – so, we talked over different solutions and they said they would e-mail pictures of their final suggestions or solutions – I will save that explanation for the end of this blog story.

We did get a chance to review all the final details and at least outline what we thought the solutions might be, but we did not get to see those details realized. That turned out to be a good thing, since some agreed upon solutions turned out to be wrong.

Then we took time to shake hands and say goodbye to the owner and the different employees we were most directly working with. We waved goodbye, got into a car and the company driver whisked us away to Incheon Airport. Nothing very exciting happened there. We passed through customs, had a quick lunch and boarded our flight. Another day, another country.

The flight to Weihai, China is actually quite short since it is in Northern China, quite near South Korea. In less than an hour we were descending into Weihai. From the air you can tell you are coming to a whole different country. For one thing, there is open land around Weihai, Lots of it, with trees and mountains and views of the Yellow Sea which laps on the shores of Weihai.

At the airport we are picked up by Shirley Wang, the lady who is our direct contact at this supplier. I will note she was driving a large Buick SUV which seems very comfortable. General Motors has a pretty substantial car business in China and I guess Shirley decided a Buick was for her. I do not remember her having own car on our last visit, but things are always changing in China.

We have a little courtesy conversation about the trip so far, the flight from Korea to Weihai. Ryan and I give Shirley a little background on our last four days as we glide swiftly and silently along in Shirley’s Buick. The trip is about 40 minutes and we pass some scenic mountains and farmlands and lots of apple trees as we zipped along on the brand new highway that now leads to Weihai

When I first visited the road situation was considerably more primitive with one and two lane roads, that sometimes were paved and sometimes were not. At night, there seemed to be no lights on any of the roads and cars had an eclectic view of which lane was going in which direction. This was not helped by the fact that many motorists did not seem to feel the need to waste battery or gas on lights that might give them an indication of what was in front of them.

The main result seemed to be cars, vans and bicycles coming from every direction – straight at you, from the side where there seemed to be no road and sometimes, even in the opposite direction of the lane you were in, some trying to get around traffic on the other side of the road, some trying to make an unscheduled U-turn on a single lane road with no room to make a U-turn, some with their headlights on, some with their headlights off.

Complicating this was the fact that this situation existed both in the country and in the outskirts of town, so often in addition to cars coming at you in the middle of a jet black night, there were also dark figures of pedestrians, old men and women, young children and everyone in between, also walking down the center of these dark streets or suddenly emerging with seemingly no direction and no purpose. No matter, it all moved and I suppose not too many people were killed or maimed each evening.

Today the highway is three lanes in each direction fully paved with huge lights poles hovering over the highway. And on this late afternoon, cars and trucks cruised along at 60 or 70 mph, everyone going in the direction they were supposed to. About 5 years ago, China strengthened their speeding and driving regulations and instituted really strict penalties on anyone not obeying them – like death for all those who drove drunk, on the wrong side of the road or who went through a red light. The result seemed to be that the whole country seemed to learn how to drive in a 3 month period and after that, all was in order, as the Germans say.

WeiHai Windmills along the highway

And so on this beautiful day, we cruised along in total order. In the distance I could see giant windmills perched up on hills slowly spinning around generating free energy. Free, that is after you pay for the hundreds of windmills that they have installed in the Weihai area in the last 10 years. But now the windmills are in place, some in the hills, some by the seaside. They are spinning pretty slowly today so I am assuming the wind was not that great that day.

By 4:30 we get to the Bliss International Hotel. It has a large lobby, like all Chinese hotels with some very large wooden chairs to sit in. They are not very comfortable, but they look impressive. We check in, present our passports. Shirley stands by to make sure they have not lost our reservation or they don’t arrest us. In a few minutes we have our passports back and we are on the way to our rooms.

Before we head up to our rooms, Shirley tells us Mrs. Zhong, her boss, will be coming to take us to dinner that evening. Shirley will pick us up the next morning and bring us to the factory. We say thanks for the ride and and see you tomorrow and within minutes I am upstairs on the 13th floor in my room, unpacking my bag, setting out my toiletries and hooking up my blue tooth speaker in order to listen to some music from the homeland.

This was the view from my room. I would swear the buildings out there were not there 3 years ago when I last visited. Things change fast in China.

This is not my first visit to this hotel. Originally, when we came to Weihai we were staying downtown in another big Chinese hotel. After staying there for four or five years, the Bliss International Hotel opened up its doors and being closer to the factory, we ended up staying there the last four or five times. When we first came to the Bliss International Hotel there was almost nothing around it. Today, it seems the hotel is surrounded by new buildings every direction.

It is a nice hotel with large open inside lobby that makes you feel like you have stumbled into Disneyland because there are a whole bunch of fake palm trees and a large mural waterfall. There are little waterways and islands where you can sit down and, if you wave frantically enough, someone will bring you food or drink.

I come downstairs at 6:30 to my find Mrs. Zhong sitting on one the giant wooden chairs. A few minutes later Ryan appears and we walk into the hotel dining room. The restaurant is buffet style in a dining room the size of a basketball court. On offer are hundreds of Chinese delicacies and a few Western alternatives. We walk around the basketball court which is littered with opulent tables holding every conceivable kind of food, vegetable, fish, or living, dead or somewhat in between. Since most of it is difficult for me to identify, I let Mrs. Zhong pick out a selection of delicacies for us, while augmenting my plate with the few things I recognize such as Chinese spinach and noodles, 2 favorites on mine.

I have found while traveling in Asia it is best to eat whatever is put in front of you. I do not recommending asking what you are eating beforehand because you may not like the answer. I remember being in Beijing one time with a Chinese customer who was taking me out to dinner – strangely, we were selling flood rescue boats to the Chinese Fire Department, which was and is a division of the military. Anyway, I made the mistake of asking what was on the plate in front of me.

Since the gentleman did not speak English and we had a lady eating with us who acted as translator, he had to think quickly how to respond after the lady translated my question.

”Meow,” he said and from that reference, I realized that I was about to enjoy fine meal of cat. I then had to go ahead and eat it. It was not too different from chicken, so I survived.

Nevertheless, I think I would have been better off if I had not asked that question.

On this night with Mrs. Zhong, we did not have cat, although there were naturally some strange things that I was not smart enough identify.

At dinner, we had some general discussion about markets, how Standup Paddleboards were faring, how they were dealing with tariffs in the States, about how we got our tariff exemption. Here, it might be instructive to mention that in the world of Asian suppliers, everybody more or less speaks English. When I first came to China, Mrs. Zhong’s English was somewhat limited, but no more. She is quick to understand all that I have to say and to respond with comments or questions of her own in English.

Mrs. Zhong has not only been a good supplier contact, she has given me advice on what Chinese books to read. Early on in our visits, I had asked her about what Chinese books to read. She quickly compiled a list of the four most famous Chinese novels…A Dream of Red Mansions, The Three Kingdoms, Outlaws of the Marsh and weirdest of all, Journey to the West. Little did I know that each of these novels was over 2,500 pages long. Nevertheless, I dutifully read them all and subsequently had many discussions with Mrs. Zhong either in person or by e-mail as to the what their meanings might be. That is a story unto itself, but these novels did give me some insight and understanding of Chinese history and the Chinese character.

One of the main businesses of my supplier was making inflatable RIB boats. They were not lucky enough to get an exemption for RIBs, so that part of their business was declining in the States. Apparently, no one in the inflatable RIB inflatable boat business in the U.S. thought to apply for an exemption. Each American company importing RIBs From China was now paying 25% more for the RIBs they were bringing into to the U.S. Sorry about that Zodiac.

My supplier was also selling into the States under their trademark – Highfield – and so the American company importing their boats had to figure out how to pass on the 25% tax they now had to pay. Sales apparently had fallen into the toilet because of that.

We talked about other things – how Mrs. Zhong’s daughter was doing and whether she planned to have another child now that the Chinese government had loosened up on their one child proclamation. The last time I was in Weihai, Mrs. Zhong seemed very positive about having a second child. This time less so. She was traveling a lot these days, she said, and she was working long hours. No, this was not the time to have a second child.

Mrs. Zhong, left us fully fed around 8 pm and that was good because we were now feeling the four days of jet lag and were happy to head upstairs for a rest. This also gave me an opportunity to call my wife – at was just after 6 am in New York and report that I was now in China.

The next morning Shirley Wang picked us up promptly at 9am Weihai time and drove us to the factory. It was only about 20 minutes away and as we drove I marveled at how all the roads had been rebuilt and how there were now new buildings and new roads everywhere.

It was another beautiful day, so I asked how do you say it is a beautiful day.

”Zhe shi meihao de yitian,” she said.

I tried to repeat it, but got it wrong.

”Zhe shi meihao de yitian,” she kindly repeated for me.

I tried repeating again and again muffed it, but after two or three more tries, I got something relatively close to what Shirley said. Then I promptly forgot it.

Within a short time, we were cruising by the little village that was located near the factory. In the past, in the fall, being corn harvest time, the little houses would have piles of corn by each door with one or two people pulling the skin off of the corn. But not today. Today the houses were empty and already partially torn down.

I asked what was happening.

“They will destroy the village very soon and the people have all moved to the new apartments that have been built for them, “ was the answer.

Yes, things were changing in China.

Within minutes we pulled up to the factory – it consisted of a large 3 story office building for administration and a larger still factory building behind it about 50 yards away, also three stories high. All of this complex is enclosed by a large wall going around a four or five acre space with an impressive metal gate that opened and shut at the push of a button.

Around the corner down the street they have another 6 buildings and several more acres of land. Those are there to manufacture inflatable RIBs, mostly with aluminum bottoms. Today we were on a tight schedule so we did not go off to see their RIB factory.

We climbed three sets of marble steps and went into a large conference room. In one corner Mrs. Zhong had a desk and she immediately jumped up to say hello. We sat down at the large conference table and began our first set of discussions covering some general points of the market, some discussion of the inflatable boat market, the inflatable kayak market and the inflatable SUP market. All 3 areas seemed to have some kind of trouble.

I went went on to outline my goals for this meeting…the first and foremost being to solve a technical problem that we were having with one of our models. I outlined my theories of what the problem was and they outlined their theories of what the problem was and since our solutions did not seem to coincide, we decided that after lunch we would go down to the factory floor and make some inspections.

That said, we went on to discuss some of the new models that we were planning to introduce. The samples were not yet ready, so there was nothing to see. So after discussing what I was hoping each new sample would show, I went on to discuss general business conditions and how our season went in the States. In many ways, I was repeating parts of the discussion we had with Mrs. Zhong the night before, but since Shirley was now present, I wanted her to hear everything in detail.

I started by discussing in detail the problems that tariffs had presented us this season and explained how we got an exemption for inflatable boats. I explained how most of the products we had gotten from them In 2019 cost us 10% more because the tariffs and how later, when the tariffs were raised to 25%, we paid a 25% tariff on 2 containers, one coming from them and one coming from our paddle and pump supplier.

This part of the discussion was particularly important for them since they had a number of American customers who were affected by the tariffs. And while the tariffs had no effect on them because they did not pay the tariffs, it had a big effect on their customers who had to pay the tariffs. The biggest effect on them directly was a decline in orders and a request from all their American customers to reduce prices because of the tariffs the American customers had to pay.

So, in the sense that tariffs did effect their sales and did increase the cost of their products to their American customers, it did have an effect on them.

I then explained in detail how we got our exemption for inflatable boats. How the National Marine Manufacturer Association wrote a letter supporting our request for an exemption saying that inflatable boats helped the entire boating industry because they introduced many new people and those people often went on to buy boats manufactured in the United States. I went on to emphasize how lucky we were to get this exemption since no other inflatable boat company had bothered to request an exemption and how only a small portion of exemption requests had even been reviewed and how a even smaller fraction of the requests had been approved.

Finally, I told them that our exemption was only temporary…after August 7th, 2020, we would either have to get our exemption renewed or hope that tariffs would be eliminated or plan to pay a 25% tariffs again starting August 7th, 2020.

In summary, I told them that this problem had been temporarily suspended, but we could not plan on it going away and we had to have plans for whatever happened in the future. In doing this, I mentioned that we were also importing boats made in Korea and Vietnam and those boats had no tariffs.

I think the most surprising thing to them was the fact that the tariffs might come back. That seemed unthinkable and indeed, it was a hard problem for me to think about. A major issue for me was the fact that this supplier generally not only had the best pricing for products that they made for us, but they generally also had the best quality. Of the two factors, price and quality, quality was always the most important issue.

Anyway, I was there to explain situation and tell them what we doing and then to set out a plan on what we going to do in the future.

We went on to have some discussions about how the season went and what they were hoping to do next year. Their report about sales in different parts of the world was almost identical to the report of our Korean supplier and very similar to our own experience. Sales were down worldwide. Yes, they were hurt in the U.S. by tariffs, but sales in Europe and Asia were also difficult. SUP sales had faded for them because there so many cheap new Chinese SUP manufacturers coming into the market. Prices of the new manufacturers were far lower than the more established manufacturers and the internet, because low prices were being offered on the internet, made it almost impossible for them to compete with the new low-priced manufacturers.

I commiserated with them, telling that our general SUPs sales were also down, but pointing out the our Sea Eagle FishSUP had been enjoying sales increases each of the last 3 years and now was becoming an important product for us. I pointed out that SUP sales were only a small part of our sales and that the core of our business was inflatable kayaks and fishing boats.

Now the manufacturer I was speaking to was one of the largest producers of inflatable RIB boats in the world, if not the largest. They had basically two businesses – inflatable boats, kayaks and SUPS and inflatable RIBs. The RIB business concentrated on aluminum rigid bottoms with inflatable sides or fiberglass rigid bottoms with inflatable sides. As mentioned, the RIBs were made in a separate factory about a half a mile away from where we were sitting and was managed, strangely enough, by a French guy who worked originally for company called Pennel e Flipo. That was particularly strange since I had originally imported inflatable boats from Pennel e Flipo about 45 years ago. What goes around, comes around.

Anyway, I gathered that the business that Mrs. Zhong was managing was having some difficulties. In particular, she told me that their Russian customers, who been among their best customers, had reduced their purchases dramatically.

Now the RIB boats, as I mentioned previously, which were sold under their trademark name, Highfield, were subject under a different tariff code # that still had the same 25% tariff we had been subject to, so this was hurting that part of their business. Considering the fact that RIB boats often cost more than $30,000 per boat, I do not know how the American importer of Highfield boats could sustain such a huge increase in cost.

I would like to point out that since tariffs are paid to U.S. Customs by the American importer (not the Chinese manufacturer) at the port before being released to the American importer, this also imposes a considerable cash flow burden on the American importer since they have to pay the full tariff before getting the RIB boats. I can only say that I am glad that was not my present problem.

By the time we discussed all of this, Mrs. Zhong and Shirley announced that it was time for lunch. Accordingly, Ryan and I got up walked down the 3 flights of stairs and got into Mrs. Zhong’s car, a Cadillac Escapade SUV. On this day, they took us into the Korean section of Weihai for a Korean barbecue meal. Mrs. Zhong does not recognize any country other than China as capable of making good food, so I always find it a little strange that she usually takes us one day to the Korean place, which, by the way, is always good.

I think this idea came when I came one time with my brother and Mrs. Zhong asked what kind of meal we would like and my brother said Korean. So after that, it became a kind of tradition to have lunch at this Korean barbecue place, although I am not sure that Mrs. Zhong actually likes the food.

You may think the Mrs. Zhong only likes Chinese food because she has never been outside of China, but you would be very wrong. She travels extensively around the world and has no doubt been subjected to all kinds of food – Korean, Indonesian, Russian, Indian, Italian, Spanish, French, German, American…yes, I am sure she has tasted it all. So Mrs. Zhong’s judgment on Chinese food is really based on an extensive testing program of alternatives and then returning to the original conviction that Chinese food is superior.

Anyway, the Korean lunch was good and soon we are wending our way back to the factory, on new roads, past new buildings. It seems to me the Weihai has more than doubled in the three years since I last visited.

Back in the factory, we go back to the conference room and sit down for more discussion. I go over my hopes for new models, I try to explain what my goal is for the new prototypes that they are preparing. In addition, I go over new improvements we want to make on existing models. Now these improvements are generally just to add features that we think will appeal to customers and make the boats more useful. Of course, each new feature adds cost so we have to ask what the added cost might be and then decide whether or not to go forward with the improvement or not.

There is another issue regarding improvements and that is the simple fact that they are usually always producing orders for us. So, in that case, we have to decide when to institute the change or changes. And then, we have to also consider if those changes need new photographs and new changes to our website, which they almost always do. So, in that case, we also have to schedule when the various improvements we are considering might actually show up in products, considering when it was practical for them to make the changes and when it was practical for us update our pictures and website.

By the time we go through all these changes in features and improvements it is getting dark and time for dinner. Somewhere during the afternoon, Shirley informs me the Mr. Koriyama will be coming by the next day.

That is a little bit a strange tale unto itself. I had known “Carl” Koriyama over 40 years ago. He was at the time the sales manager for Achilles Boats and because we were often at the same trade shows, we got to know each other.

The last time I had seen Mr. Koriyama was in Genoa when I was visiting the Genoa Boat Show. It happened that he and I were staying at the same hotel.

After Mr. Koriyama left Achilles, he formed his own company called “JoyCraft” and now, many years later, he is using my Chinese Weihai supplier as one of his suppliers. Small world it is.

I tell Shirley I will be most happy to see Mr. Koriyama, who said that he wants to stop by and say hello. Since he is coming from Japan, that is not as simple or as close as coming from Korea. The flight from Osaka is a good 4 hours, so I have to be very happy someone will come that far to say hello.

After talking for the whole afternoon, we get into Mrs. Zhong’s Cadillac and head to a Chinese restaurant. As you enter this particular restaurant, you pass aquarium tanks filled with different living fish and other sea critters, such as shrimp, sea urchins, and other creepy, crawly things that come from the bottom of the sea. But that is only a small part of the visual selection of Chinese seafood that is presented us. We also pass stainless steel containers of mounds of fish, shellfish, eels, crabs and other critters.

Some yummy fish

Needless to say, Ryan and I leave everything in the capable hands of Mrs. Zhong, who quickly collars some restaurant order taker who faithfully writes down everything Mrs. Zhong barks out to him. Ryan and I pick out a few basics that at least we can recognize. Mrs. Zhong, not satisfied with our meager selection, adds multiple items to the order. After that we are led ahead to a room with a large table where Mrs. Zhong, Shirley and 2 or 3 other of our supplier’s employees sit down to join us. So, now there are 6 or 7 people sitting around this large table. Waiters and waitresses wander in and out placing things of the lazy susan table that is rotating various selections to take.

More Weihai seafood at the same restaurant

Weihai is a seafood town. I am particularly fond of the Weihai clams. In any case, we have a fine meal, with a vast selection of different seafoods and all is good.

After a couple of hours, Mrs. Zhong whisks us back to our hotel where I can settle back to listen to some American rock in my room and give my wife a call.

On day 2 in Weihai, we are picked up at our hotel by a company driver and then whisked off to the factory. The morning is spent in more discussions on quality issues, new improvements, a general discussion of goals for the visit. Often we repeat ourselves some of the points made the day before. These supplier visits are always like that. We state a bunch of stuff, we discuss a bunch of stuff and then we go over it all again. And the reason for that is simple: you have to go over things multiple times to be sure your point of view and desired changes are fully understood.

We come 8,000 miles on a once a year to try and discuss every problem, every hope, every dream, every wish we have. This is really the only time we have to do that and like it or not, there always some language barrier and some cultural barrier. Suppliers have a tendency to always say yes and it is only prudent to repeat what they are saying yes to to be sure they really mean yes. They wish to be polite, but if you come 8,000 miles you wish to be precisely understood and the word “yes” does not always mean you are precisely understood.

On the factory floor or should I say factory table, taking a break from discussing some quality issues.

We find that out later when we go down to check some of the boats were were having a quality issue with. Despite explaining the problem in what you think is the clearest way, when we get down to the factory floor, we find some of the problems still exist. And so, we have to go on to discuss those problems once again, repeating in some different ways what you said previously. Asian people are incredibly smart and usually they understand most of what you a trying to get across, but sometimes they miss a part of what you are saying and in their effort to please they say yes, when they really do not fully understand what you are asking.

So the problem between importer and supplier is complex and it requires patience and repetition. The hope is always by the time you are done with your visit everything is clearly understood and being acted upon. Regrettably, that is not always the case.

So we launch into more extended conversations, going point by point, asking questions, getting answers, discussing problems, suggesting solutions. About an hour into conversation, Mr. Wang, the owner the company comes charging in, shakes hands, asks how things are, hangs out for a few minutes and rushes out to his office, which is down a flight of stairs.

Sometime before lunch, Mr. Koriyama arrives. He is much the same man I remember, thin and trim, but more fastidiously dressed. We shake hands, commiserate on our advance ages and exchange stories of how active we are. I feel somewhat undressed since I am in boating testing clothes – jeans, country flannel shirt, loafers.

Mrs. Zhong, Mr. Koriyama and casually dressed me

He still drives a car he tells me. He still travels to meet suppliers. He still works on new designs. I tell him that I also try to stay active and work on new designs. We exchange catalogs and business cards.

His company, JoyCraft, seems to be a quite stable and ongoing business in Japan. I am unable to read the Japanese in his catalog but he seems to have over 50 different models. That is a lot since we have over 30 models ourselves and we spent over 50 years adding new models. Anyway, it seems that Mr. Koriyama has found a good market for his products in Japan. I noted from his catalog, that he, like us, has many unique models, most of which are focused on the fishing market.

After some conversation, I tell Mr. Koriyama that later that day we are going to test some new models and if he would like, he is welcome to come along. He says he will. Then, Mr. Koriyama goes off to say hello to Mr. Wang, the company owner.

Since we do not have a lot of time and still much to do, I suggest to Mrs. Zhong that have sandwiches brought in for lunch. I can tell from the expression on Mrs. Zhong’s face that suggestion will not fly. It would be un-Chinese to have sandwiches, so we settle on steamed dumplings, which, after more conversation, are duly ordered along with some Chinese fish soup. After some more conversation, some more repetition of points and a whole lot of questions, the food arrives.

Before mentioning more, I have to point out another aspect of a supplier visit is asking endless questions. I like to take the opportunity to ask as many questions as possible about different manufacturing techniques, different alternate materials, different construction methods.

On this trip, I am most interested to know the difference in cost, weight and labor in making round tube construction versus drop stitch construction. Round tube construction is making round shapes using one layer of 1000 denier PVC/polyester fabric. Drop stitch construction is making flat, rectangular shapes using 2 layers of 1000 denier fabric with hundreds of 1,000s of polyester threads going up and down between the top and bottom layers. A complicating feature of drop stitch construction is the fact that drop stitch construction usually employs two additional layers of 1000 denier PVC/polyester fabric top and bottom. The extra top and bottom layers are generally called wraps.

So one of my missions was to understand the exact cost, weight and labor differences between the two different construction methods. I will mention that on this trip I also asked my Korean supplier the exact same questions. Now Shirley or Ms. Wang, as I call her alternately takes this mission very seriously, so with each technical question I ask her in the conference room, she promptly calls the factory, which is about 50 yards from the large office building that I am in. Since, I also have multiple other question about fittings, molds, D-rings, grommets, mounting brackets, handles, Shirley has to spend a good portion of this day calling her technical guys and retrieving answers, which also takes the time of a technician to delve into. My questions will probably take a major portion of this day (excluding the time we will with boat testing), but gradually, I am assembling answers to all my questions.

Now, you may think a guy who has spent 52 years working on inflatable boats would know everything and anything there is to know about the subject. And while it is true that I do know a lot about the inflatable boats and inflatable products, things change, things evolve, and the more I know, it seems there is still far more to learn. And so it goes.

And now back to lunch, just as the dumplings and soup arrive, Mr. Koriyama wanders back in and we all sit down at the big conference table for really pretty nice feast of dumplings and soup. It seems there are several varieties of dumplings, a simple fish broth soup, water, Coke , and, of course, tea. I steer clear of the Coke, not having touched that beverage in the last 30 years.

During lunch, I make the mistake to ask Mr. Koriyama where in Japan he comes from. He answers “Hiroshima”. My heart sinks and for a few moments I can say nothing auditory other than repeating several times, “Oh, my God.”

It happens that I had a uncle, Joe Cunningham, who arrived in Hiroshima 3 weeks after the bomb had landed. He told me that it was the single most horrifying time of his life, that he saw things so terrible that he never wished to repeat them, that for several weeks thereafter he had kind of given up on the human race and actually considered suicide. He did not, of course, commit suicide, but he did tell me some of the horrifying details that I will not mention here.

And so, I could only be terribly sad and moved when my old friend and colleague mentioned “Hiroshima”. It was something I never knew about him and I never remembered him mentioning this during the many times I met and talked with him at trade or boat shows.

After my first hesitation about this subject, I was able to ask some questions about how he had survived this terrible event. It seems he was 5 years old at the time the bomb was dropped. That would make him 2 years older than me. Fortunately, he was 40 miles or so away at a school, so he did survive. I assume that he must of had many relatives and friends who were either killed or injured by the bomb. And of course, you must remember, because radiation was involved, some of the injuries only became apparent and fully understood years later. As you may or may not know, birth defects were a common result in women who happened to be pregnant at the time. So the event was both terrible immediately and terrible over time. And of course this is not to say what was right or wrong about World War II, only to mention how this event in the war must have shaped Mr. Koriyama’s mind.

The lunch was filling and pretty soon we are ready to go off to test boats.

So, we pile into several cars and the technicians gather several boats and motors and place all of that in a fairly large flatbed truck. In truth, on this day, we are not testing new models. Rather, I am testing some prototypes of models we have produced by another supplier. We are considering moving production, at least temporarily, of these existing models because they probably will allow us to offer these existing models at much better price to American consumers.

This another aspect of having multiple suppliers and multiple models. Sometimes you shift them around for cost and marketing reasons. In particular, I see an opportunity, while we have an tariff exemption on Chinese made boats, to offer transom boats at much better values. And so we are testing these prototypes to consider that change.

On the way to our boat testing, I get to talk with Mr. Koriyama about old times in the inflatable boat business. After that, as we wend through the back roads of WeiHai, I move on to the discussion of the situation between Korea and Japan. I want to get Mr. Koriyama’s opinion of the present state of affairs between the two countries. I tell him about the reaction I got from some of my Korean contacts on situation. Mr. Koriyam’s first comment is instructive:

“When will our apologies be enough?” he asks.

He goes on cite how he thinks Japan has apologized and tried to make good.

However, considering the seriousness of the allegations, I am sure the answer is that Korea will never be fully satisfied with Japan’s apologies or financial efforts to make good. I mean no one wants their daughters and mothers pulled from their homes and families to be used by the men of an invading army. Again, this is not to say what was right or wrong, but rather to admit what happened.

Mr. Koriyama goes on to fill me in on the Japanese side of the story. Yes, it was a terrible fact of the war and of the Japanese occupation of Korea. But in truth the Japanese had apologized and paid reparations many times and still Korea was not satisfied. Of course, the truth is when something terrible occurs there never is truly a satisfactory resolution. Some things will never be forgotten.

Then Mr. Koriyama goes on to insert his own more light-hearted view of the matter which was novel to say least:

“I think it is the Korean food. It’s just too spicy…too many hot peppers.”

Personally, I always considered this more of a Mexican problem, but no matter. I do not want to dispute the origin of bad feelings and bad blood. Obviously, it is still there. And in fairness to Mr. Koriyama, when he made the spicy food comment, he was just trying to lighten up the conversation.

Off we go. Our first foray into Weihai waters is not successful. We head to a small fishing harbor where there a lots of scenic fishing boats with motors that look like they were last serviced in the 1930s.

Weihai fishing boats with well-used motors and a shadow of me

That turns out to be a very nice scenic location with one problem. It turns out to be low tide and there is not enough water or any good way to get to it, so it is decided to move the troops elsewhere. And off we go.

The next location turns out to be more practical, just still somewhat challenging. After driving another 5 or 10 minutes we arrive there. The technicians are hauling boats and motors down a steep embankment onto a side canal which leads out to some rather nice ancient Chinese canal waterway that seems ideal for testing and also seems to be tidal.

Just heading out for testing

The boat testing turns out to be disastrous, with neither of the 2 boats we tested working properly. Something in prototypes must different because these 2 prototypes do work properly at all. Instead of easily getting up on a plane, they plow forward with bows so high you can hardly see where you are going and they do not easily get up on a plane. This was not what Ryan and I were expecting, but it was what happened. It takes me only a few minutes in each boat to say further testing is useless and the present prototypes are unacceptable. And so it goes sometimes.

I have to say the testing did not go how I thought it would. This same supplier had made these same boats about 12 years earlier and the boats they made at that time had zero motoring issues and got up almost instantly on plane. So I was truly astonished that these prototypes did not work, but that was the fact. They were a no go.

Mr. Koriyama saw the problem almost immediately and started whispering in my ear the word “water tunnel”. By that I think he meant that the floors and the transoms of these 2 boats were not quite high enough in relation to the round side pontoons. And in truth, later on, this observation turned out to be right. At that moment I was not ready to conclude anything other than the two prototypes were of no use.

We piled back into the cars and technicians loaded up the motors and the boats into the truck. In truth, Shirley and Mrs. Zhong seemed as surprised as Ryan and myself. All of us had assumed that this test was going to be merely a confirmation that the prototypes worked perfectly and of course, the opposite was the result. Perhaps, Mr. Koriyama knew in advance. If so, he was polite enough not to mention it.

We cruised back to the office, had some further discussion of the problems we saw in the testing. Mrs. Zhong, sensing that I had quickly given up on this project and not wanting to give up, said, no, they will discuss this problem in the morning and remake the samples, retest the samples one or two weeks later and send one or both to us, if they worked correctly, by air at their expense. That was really the correct way to approach and possibly solve the problem. And, in fact, that is what ended up happening.

After going over the problems of the two prototypes, we moved back to the factory floor to discuss another prototype that I was working on. That was a weird 3 pontoon cruise about boat that I had been testing an earlier prototype of all the past summer. I wanted to changed some of the dimensions and make it handle a shortshaft 10 hp motor better. The original prototype worked great but the transom was too high to handle a short shaft motor. I had used all this last summer with 2 electric motors and two solar panels – it worked great.

This is the TriTiki that I have been testing all summer as a true solar powered boat. It worked great. Unfortunately, the newer prototype had issues.

Unfortunately, the newest prototype also had issues. The main change they were supposed to make was to make the 3 pontoons 16″ instead of 19″. Instead, for reasons beyond my understanding, they made the center pontoon 16″ and left the two outer pontoons 19″. I had named this new model the TriTiki 16. Again, the new prototype was just not ready for prime time.

The last prototype I was working was new smaller, lighter weight version of our Sea Eagle FishSkiff. It turned out because of the press of time that prototype was not ready. So you could say we struck out four times. Not good, but sometimes things do not roll your way. Anyway, we decided to call it an evening.

From the factory, we moved directly to dinner. That turned out to be a particularly elegant seafood restaurant located right on the water in Weihai.